Understanding Precision Die Cutting

Precision die cutting is a fundamental process within manufacturing that leverages advanced techniques to create parts and products with high accuracy and efficiency. This process involves cutting materials into specific shapes using specialized dies that guarantee uniformity and detail, making it an invaluable asset in various industries. The significance of precision die cutting lies in its ability to reduce waste, enhance product quality, and streamline production processes.

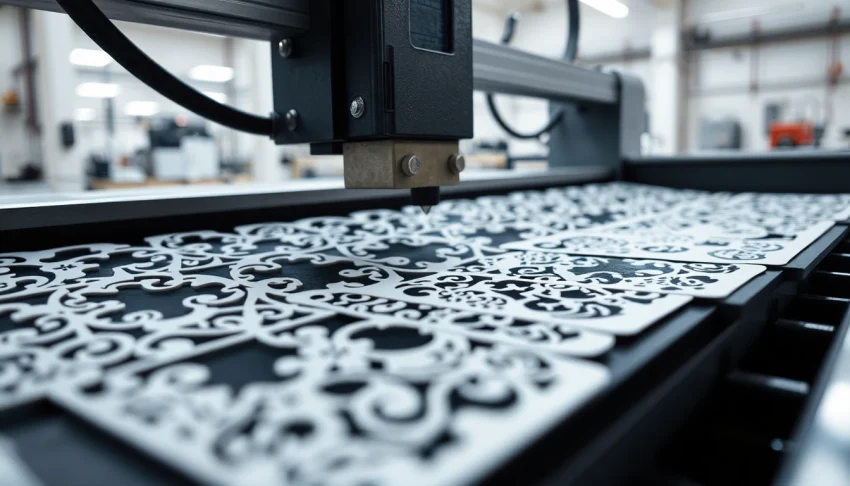

What is Precision Die Cutting?

Precision die cutting refers to the process of using a die to cut materials into specific shapes and sizes with high accuracy. This is achieved through the application of precise pressure and computer-controlled machinery. Industries ranging from automotive to consumer goods rely on this technique to produce a plethora of components that meet stringent design specifications and tolerances. The materials used in precision die cutting can vary widely and include flexible materials such as paper, plastics, rubber, and metals.

History and Evolution of Die Cutting Techniques

The origins of die cutting can be traced back to the early 19th century, when manual processes laid the groundwork for modern techniques. Initially, die cutting was performed using simple presses and rudimentary tools. As manufacturing technologies evolved, so did die cutting methods. The introduction of computerized technologies in the latter part of the 20th century revolutionized the industry, allowing for higher precision, greater efficiency, and the ability to handle complex designs that were previously impractical.

The Importance of Precision in Manufacturing

Precision in manufacturing is crucial as it directly correlates to product quality and reliability. In industries where tolerances are tight and specifications are critical—such as aerospace, medical devices, and electronics—flaws in components can lead to failures or safety issues. Therefore, achieving precision through die cutting not only improves product compliance with regulatory standards but also contributes to cost savings by minimizing material waste and reducing rework.

Types of Precision Die Cutting Methods

There are several methods of precision die cutting that each offer unique advantages depending on the application and materials being used. Understanding these methods is critical for manufacturers looking to optimize their production processes.

Flatbed Die Cutting: Pros and Cons

Flatbed die cutting is a method that utilizes a flat die and a hydraulic press to cut materials. One of the key advantages of this technique is its ability to handle thick materials and produce intricate shapes. However, it often requires longer setup times compared to rotary die cutting. This method is best suited for short runs where flexibility in design is necessary, but mass production efficiency may be compromised.

Rotary Die Cutting Explained

Rotary die cutting employs a cylindrical die that rotates as materials pass through. This technique is particularly effective for high-volume production runs as it allows for continuous cutting while reducing cycle times. The precise and consistent pressure generated by the rotary press enables cleaner cuts and finer details, making it ideal for applications in packaging, labels, and fasteners.

Innovative Techniques in Precision Die Cutting

Recent advancements in technology have led to innovative die cutting techniques, such as laser die cutting and digital die cutting. Laser die cutting offers heightened flexibility as it uses laser beams to cut materials without the need for physical dies, allowing for rapid prototyping and complex designs. On the other hand, digital die cutting uses computer-controlled blades to create cuts and shapes, combining the speed of traditional die cutting with the precision of digital tools.

Applications of Precision Die Cutting

Precision die cutting is utilized in a wide array of industries due to its adaptability and efficiency. Understanding the various applications can provide insight into the process’s importance across different sectors.

Industries Utilizing Precision Die Cutting

Some of the primary industries that benefit from precision die cutting include:

- Automotive: Used for gaskets, insulators, and sound-deadening materials.

- Medical: Creation of custom surgical instruments and components for medical devices.

- Aerospace: Production of lightweight, durable parts that comply with strict safety standards.

- Packaging: Development of intricate designs for various packaging materials and containers.

- Electronics: Making components such as insulation and circuit board materials.

Case Studies of Successful Implementations

Many companies have successfully integrated precision die cutting into their production processes. For instance, an automotive manufacturer implemented rotary die cutting to improve the production of foam insulation parts, resulting in a 30% reduction in material waste and a significant increase in production speed. Similarly, a leading medical device firm adopted laser die cutting for the rapid prototyping of surgical instruments, allowing them to expedite the product development cycle while ensuring tight tolerances.

Trends in Precision Die Cutting Applications

As technology progresses, new trends in precision die cutting continue to emerge. Notable trends include:

- Sustainable Practices: Increasingly, manufacturers are seeking ways to utilize eco-friendly materials and reduce waste.

- Integration with Automation: The rise of automation technology allows for seamless integration into production lines, further enhancing efficiency.

- Customization: Customers increasingly demand tailored products, pushing manufacturers to adopt flexible die cutting solutions that can accommodate small batch sizes.

Choosing the Right Precision Die Cutting Partner

Selecting the right partner for precision die cutting is a critical decision that can significantly impact production efficiency and product quality. To make an informed choice, consider the following key factors.

Key Qualities to Look For

When evaluating potential die cutting partners, look for the following qualities:

- Experience: A partner with extensive experience in your industry will understand specific requirements and challenges.

- Technology: Leveraging the latest die cutting technologies can enhance precision and efficiency.

- Quality Standards: Ensure that the company adheres to international quality standards and best practices in manufacturing.

- Flexibility: Look for partners that can accommodate both large-scale production runs and specialized, custom orders.

Cost Considerations for Precision Die Cutting Services

The cost of precision die cutting can vary greatly based on several factors, including the type of die cutting method used, volume, material type, and design complexity. Generally, here are some cost considerations:

- Die Creation Costs: These can range significantly, with custom dies often requiring an upfront investment.

- Material Costs: Prices will fluctuate based on the type and source of the material used.

- Labor Costs: Efficiency in setup and production can significantly affect the overall price.

- Volume Discounts: Higher production volumes typically lower the per-unit cost due to economies of scale.

Frequently Asked Questions About Precision Die Cutting

As industries continue to adopt die cutting technologies, several common questions arise:

- What are the tolerances for die cutting? Tolerances generally fall within +/- 0.005 inches, although this can vary based on material and design specifics.

- How much does die cutting cost? Average die costs can range from $250, with yields typically exceeding 8,000 impressions depending on material and design.

- What is the difference between rotary and flatbed die cutting? Rotary die cutting is typically faster and offers more precision, while flatbed die cutting is often more versatile for different materials.

Best Practices for Precision Die Cutting Projects

To ensure successful outcomes, implementing best practices in precision die cutting projects can vastly improve results. These practices help in maximizing quality while minimizing waste and cost.

Design Considerations for Optimal Results

Effective design plays a crucial role in the success of precision die cutting projects. When designing components, consider:

- Material Selection: Choose materials conducive to easy cutting and desired final characteristics.

- Design Complexity: While complex designs can be executed, they may require more sophisticated die cutting techniques, increasing costs.

- Tolerance Specifications: Ensure that tolerance levels are clearly defined to guide manufacturing accurately.

Quality Control and Testing Procedures

Establishing robust quality control measures is essential in maintaining consistency and accuracy in production. These procedures can include:

- Regular Inspections: Implementing routine checks at various production stages ensures adherence to specifications.

- Testing Samples: Producing sample runs for testing before full production can detect potential issues early.

- Feedback Loops: Establishing channels for feedback from production staff can help identify inefficiencies or problems in real time.

Measuring Success: Metrics for Precision Die Cutting

To evaluate the success of precision die cutting projects, consider tracking specific metrics:

- Yield Rate: Measure the percentage of acceptable parts produced versus total parts completed.

- Production Speed: Monitor the time taken to complete production runs relative to set targets.

- Cost per Unit: Calculate the total costs associated with production to assess profitability.